When and how to change the brushes on the washing machine

The washing machine is one of the most important household appliances. Modern machines save you time and nerves by being equipped with innovative technologies. Modern washing machines are also combined with dryers that can dry clothes, regardless of whether you are at home or not.

It's true that many of us don't replace our machines very often. Washing machines can last a long time, but they do require periodic maintenance. If you've had your machine for more than 5 years, now might be the time to buy a new one that's packed with modern features.

These are inverter and non-inverter technology. You may have heard of air conditioners and refrigerators that are equipped with a similar motor. And what is a washing machine with a brush motor and what are the advantages? Inverter machines are controlled by a special board, which is an inverter. It works with high voltage and thus drives the motor. In washing machines with brushes, the motor is a collector one.

In general, there are two types of machines that are widespread. One is inverter, and the other is with a brush motor. There is also a third type of appliance that has a capacitor, and these machines are from the 1st generation. Washing machines with a brush motor are from the 2nd generation. And the 3rd generation are inverter machines.

Some technicians like to say, “No brushes, no problems.” But when the electronics of inverter washing machines fail, then the repair can be overwhelming for consumers. At the same time, the brush motor is noisier, but on the other hand it is much more reliable. The good news is that it is significantly more cost-effective to repair compared to the inverter motor.

The motor brushes are available in two sizes – 13.5 mm. and 12.5 mm. Only on Miele washing machines are they of different length and width. When replacing the brushes, be very careful not to reverse their direction, because sparks will appear during operation. This will eventually damage the collector, and from there you will have to repair the motor.

Before the brushes run out, an unusual noise is heard from the washing machine, which can be likened to a scraping sound. In addition, sparking will occur during the spin cycle. Such problems with the washing machine can confuse the user. Only a technician would determine the real cause of the defect in the machine.

After replacing the old brushes, it is advisable to run the washing machine on an empty program, the speed of which reaches a maximum of 400. The speed can be gradually increased for subsequent washes. For the second start of the washing machine, fill the drum to half, again selecting programs with low speeds.

After 2-3 washes, you can return to the usual operation of the machine, as before replacing the brushes. They last about 6-7 years with a higher load on the washing machine. And if you use the machine less often, the brushes can last up to 10 years. Their distinguishing feature is their strength. However, it is recommended that if you replace them, the new ones be made of a relatively softer material. They will wear out in a shorter period of time than harder brushes. However, the new ones will not damage the collector.

Many stores sell brushes made of strong graphite. The material is resistant to friction, but has a detrimental effect on the collector. Gradually, it gives a defect and leads to damage to the motor, which then has to undergo major repairs. This is an eloquent example of a situation where the brushes remain healthy, but the washing machine motor breaks down.

By the way, repairing the machine requires replacing both bearings so that they do not make noise. Keep in mind that when replacing the brushes, sandpaper should not be used to adjust the graphite. This changes their position, which also leads to the appearance of sparks. The collector will again suffer, which begins to overheat. And in this situation, the engine will need to be repaired, even if the brushes are new.

.

Carbon brushes are small but crucial components that help the machine function. They are what conducts electrical current between the stationary and rotating wires inside the motor.

Brushes are among the most exploited elements in machines and wear out over time. Once such a defect occurs, you may notice problems in the operation of the washing machine. Early identification of the problem can help you replace them quickly, while preventing further damage to the machine's motor. How do you know if your brushes need to be replaced? The following signs will give you a better idea of the appearance of a possible defect:

- Reduced washing machine performance: The machine may stop working or not reach high speeds as before.

- Lack of power/Unstable voltage: If the brushes are worn out, the washing machine starts to operate unevenly.

In most models, these parts are located near the motor housing. You just need to remove the cover, which is held in place by screws. Take a good look at the brushes and if you notice any carbon buildup or a very small amount of carbon, then you should replace them. - Sparking: Although minimal sparking is common in some household appliances, frequent sparking is not. This may be due to poor brush-to-collector contact surface. They should match the commutator arc, however. This ensures proper surface contact. The cause of sparking is excessive brush wear, commutator damage or contamination, and improperly installed brushes.

- Burning smell: If such a problem occurs, you should immediately stop using the washing machine and seek a solution.

- Can brushes be repaired? The answer is: no. What you need to do is replace them with new ones. Replacing them is much faster and more convenient if you call a technician.

What is needed to change the brushes:

Wrench

Screwdriver

Turning off the washing machine |

Removing the rear panel or cover. Dismantling the motor |

Replacing the brushes |

These are the individual stages of their replacement:

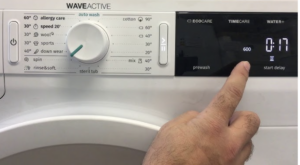

Step 1 – Unplug the washing machine.

Step 2- Remove the cover to access the engine.

The motor is located at the back of the machine. Disconnect all hoses and remove the back panel from the washing machine. The motor is located under the drum. On some models, you may not need to remove the motor to remove the carbon brushes.

Step 3 – Dismantling the engine

First, you need to remove the drive belt from the drum pulley. Then, remove the cable block and the grounding plug connected to the motor. Using a wrench, you need to remove the mounting bolts holding the motor. This will allow you to pull the motor out, but be aware that you may need to apply a little more force.

Step 4- Replacing the old brushes

They are held in place by screws and go into the switch at an angle. To make sure you put them in the right way, you need to remember how the old ones were positioned.

Step 5 – Installing new brushes

The carbon of the new brushes should be exposed before connecting them to the motor. When replacing them, it is necessary to place them at an angle. For your convenience, the brushes are supplied with special pins, which allow them to be connected correctly to the motor.

Proper maintenance of your washing machine will ensure trouble-free and trouble-free operation for many years to come. For this purpose, always use the services of an authorized household appliance repair shop.